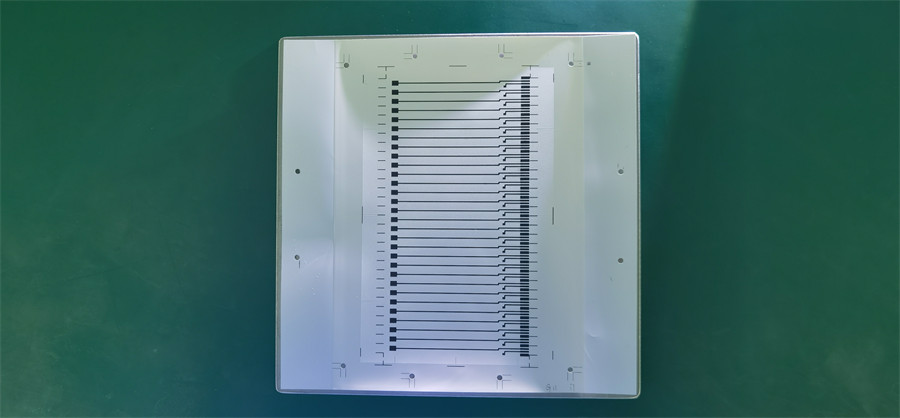

Heater printing:

the graphic position deviation can be controlled within 30µm. By adjusting the viscosity of the electronic packaging materials on heaters and detecting the thickness, the batch thickness deviation is guaranteed to be less than 0.5µm. The heater resistance can be controlled at 2.5±0.30Ω, which effectively solves the problem of large batch differences in heater resistance caused by uneven printing thickness. By monitoring the viscosity and thickness of the electronic packaging materials on the insulating layer, the insulating effect of the insulating layer on the heater is guaranteed, avoiding leakage caused by poor insulation.